PRODUCT

صفحة رئيسية>منتجات>

استجواب

عندما تلقينا استفسارك ، ونحن سوف نرسل لك كتالوج مخصص ، وقائمة الأسعار ، والتسليم ، وشروط الدفع وغيرها من التفاصيل المطلوبة عن طريق البريد الإلكتروني خلال

cone crushers unit

Cone Crushers Moore Watson Ltd

MHP series Cone Crushers are compact units and used in a wide range of applications. Well suited with its unique combination of speed, throw and cavity design providing maximum production with superior performance, Sandvik UH412 is a secondary crushing unit fully assembled on a single trailer frame. With its efficient four-deck vibrating screen and powerful Sandvik CH440 cone crusher, this Sandvik CH440 Cone Crusher With A Robust Crusher Design2022年1月21日 The world's most popular modern cone crushers. HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing HP Series cone crushers – High performance

Cone Crushers - Westpro Machinery

2023年9月6日 Westpro’s high productivity cone crushers are available as standalone units, modular assemblies, portable assemblies and as part of modular crushing plants. The 2 天之前 Parker Plant offers two types of cone crushers: the standard speed bronze bushing design the high-speed bronze bushing design (GC Series). The Standard Cone incorporates modern user-friendly features Cone Crushers - Parker PlantDriven by quality and built for rock, the Sandvik UH373 is an open circuit Sandvik cone crusher modularly designed so that several different cone crushers can be mounted on the same platform. The UH373 is an open UH373 Cone unit — SRP

UH311 wheeled cone unit - SRP

Sandvik UH311 is a compact secondary and tertiary crusher fully assembled on a single trailer frame. Equipped with a four deck screen for accurate and efficient screening, 2023年9月6日 Westpro’s portable jaw and cone crusher units deliver self-contained crushing solutions for quarries, remote sites and construction projects. These crushers Portable Crushers - Westpro MachineryCone crushers of various sizes and modifications are used widely for rock processing now. ... During the operation of crushers, large dynamic loads act on their main units, leading to wear and damage to the seats of the support bodies and the crusher bowl. One of the main elements of a cone crusher is a crushing cone (armor), the surface wear ...Usage advanced technological methods for the recovery

McLanahan CMB Cone Crushers

The controls of the CMB Cone Crushers comprise a contactless in-cylinder transducer and an operating console that can be positioned close to the crusher. Quick release, self-sealing couplings are used to connect the twin hydraulic hoses that run between the crusher and console. The console houses the fluid tank, motorized hydraulic pump, valves ...MEKA cone crushers are an excellent choice as secondary crushers in combination with a jaw or a primary gyratory crusher or in the third or fourth crushing stage. ... • The oil tank for the lubrication and setting adjustment Cone Crushers – MEKA2016年1月1日 In this paper a cone crusher is modelled and simulated using DEM in the commercial software EDEM® provided by DEM-Solutions Ltd. Cone crushers and gyratory crushers have previously been the subject for DEM modelling and simulation. Lichter et al. (2009) successfully modelled a laboratory B90 cone crusher.Cone crusher modelling and simulation using DEM

Mobile crushers and screens - SRP

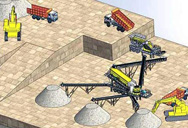

Mobile crushers and Screens. We offer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions. This selection includes jaw crushers, impactors, cone crushers, screens and scalpers for quarrying, construction and rock excavation projects.2021年6月24日 fi tted with jaw, cone or impact crushers, with or without screens, and equipped with open or closed circuit and discharge conveyors. Mobile screens – track-mounted units for ex-cellent mobility and high performance on-site. Ideal for a wide range of applications. Also mobile screens on wheels which incorporateCrushing and Screening Handbook - AusIMM2022年1月21日 ® HP Series™ cone crushers The world's most popular modern cone crushers HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design. As the name suggests, these proven and reliable universal crushers deliver High Performance in quarrying and mining HP Series cone crushers – High performance

® HP Series™ Cone Crushers Brochure

new generation cone crushers: Keeping you ahead There's no better choice than a cone crusher when it comes to . . . • high productivity, • low operating and wear costs, • long service life, and high product yield with desired shape and gradation. Metso leads this market with its high performance HP Series cone crushers for the aggregate and mining Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always). Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft , mantle , concaves , cone , eccentric bushing , drive , crown gear , frame , and tramp release mechanism (mechanically or hydraulically actuated).Cone Crushers (Parts of a Cone Crusher) Explained - saVRee2022年11月21日 Kubria® cone crusher (1,100 mm cone diameter) in a quartz porphyry works Feed grain size 5 – 32/44 mm Product size 0 – 22 mm Throughput approx. 150 t/h Kubria® cone crusher (2,100 mm cone diameter) for crushing granite Feed grain size 75 – 350 mm Product size 0 – 75 mm Throughput approx. 800 t/h Two Kubria® cone crushersIndustrial Solutions Kubria cone crushers - ThyssenKrupp

Cone Crushers Moore Watson Ltd

Cone crusher Cone crushers CC100 CC200 CC400 CC300 MHP400 MHP500 / top of page. MOORE WATSON LTD. Consultancy, design and manufacture of mining, mineral processing and recycling equipment. ...Consult Metso Automation's entire MP 1000 and MP 800 Series Cone Crushers catalogue on DirectIndustry. Page: 1/16. Exhibit with us {{>currencyLabel}} ... MP800 can process more ore to the same reduction or the same quantity of ore to a finer reduction than any competitive unit. Yet each is designed to fit onto a 7 ft. Symons cone ... MP 1000 and MP 800 Series Cone CrushersMobile and stationary units, plants and automation solutions for aggregates production. View products Spare and wear parts ... Fine crushing with cone crushers. Due to their design, cone crushers are generally a more expensive investment than impactors are. However, when correctly used, a cone crusher offers lower operating costs than a ...Crushers - All crusher types for your reduction needs - Metso

Sandvik CS430 Cone Crusher For Secondary Crushing

QS332. Sandvik QS332 is a compact, robust mobile secondary cone crushing solution designed for versatility and ease of operation. Fitted with Sandvik CS430 "S" type gyratory cone crusher, it is capable of accepting large feed sizes whilst achieving high production capacities. QS332 Mobile unit.Demand more from your Metso® MP™ crusher with our high performance spare parts and liners. Our spare parts do more than replace the components in your Metso® cone crusher—they improve its performance. Get a longer wear life, better efficiency, increased safety and more throughput with EXCEL™ replacement parts.Spare crusher parts for Metso compression crushers: EXCELGyratory crushers. Gyratory crushers can be used for both primary and secondary crushing. They are similar to cone crushers as they both have cone-shaped rotating shafts. The spinning shaft is used to crush the material against the wall of the crusher. Reduction ratio = 8:1. Cone crushers. Cone crushers also have shafts that move back and forth.What is a Primary Crusher? - Crushers, Excavators, Conveyors

UH311 wheeled cone unit - SRP

Wheeled cone units. UH311 Cone unit Equipment Sandvik CH430 cone, SA1854 four deck screen Max. feed size 185 mm (7 in.) ... Also available in this range of wheeled cone crushers is Sandvik UH312, UH316, UH412 and US316. Additional advantages Quick to set-up and easy to maintain, resulting in higher uptime and increased productivity ...Our range of mobile jaw crushers is one of the most comprehensive on the market, led by the international bestselling Sandvik QJ341 mobile jaw crusher. Our mobile cone crushers are designed to provide the ultimate in versatility; each of our models crushes aggregate to almost any size. Our hydraulically-adjusted Sandvik Hydrocone crushers are ...Mobile Crushers, Mobile Jaw Crushers Mobile Screens - SRP2 天之前 The GC series of cone crushers feature a highly rugged, more compact design than the standard cone. ... Incorporating the well proven fully hydraulic Parker Cone Crusher, this unit is ideal for working in a composite crushing arrangement with Parker primary crushing plants, screens and conveyors. Tracked Cone Crushers.Cone Crushers - Parker Plant

Raptor® Cone Crushers for Aggregates -

Our line of Raptor Cone Crushers is the most diverse product line on the market, including a broad range of sizes and features. For aggregate applications, we recommend the Raptor R250 to the R450, though we also offer larger raptor crushers that are typically used in mining or larger aggregate sites.No matter which model you need, you can be confident

- تن از سنگ شکن

- سنگ شکن سنگ باریت شن و ماسه سنگ ساخته شده در چین

- حفارات الصخور كسارة للبيع

- تكلفة كسارة فكية متنقلة Uj I

- مطاحن أسطوانة تغذية الخنازير

- جهاز كسر البنات

- مشتتات مركب كربونات الكالسيوم

- rerd شراء مطاحن خولنا الجوت

- كين RC1 التفكيك الذهب صخرة محطم

- أبك فرس النهر المطاحن

- مدارس تعليم المعدات الثقيله فى تونس

- تستخدم مصانع السحق والفرز المحمولة

- استقرار الرصيف باستخدام نفايات خام الحديد

- أداة ثلاثة مطحنة

- محطات معالجة خام الذهب الصيني

- شركات مبيعات معدات التعدين

- الكروميت آلات استخراج

- بثق النحاس

- كسارة فكية 50tph مع المغناطيس

- النحاس الموردين خام الشيلي